Fly rod cases from start to finish

Beautiful hardwoods ready to be used. Canary Wood, Cherry, Padauk, Mahogany, Red Oak, Walnut, Wenge, and Zebrawood.

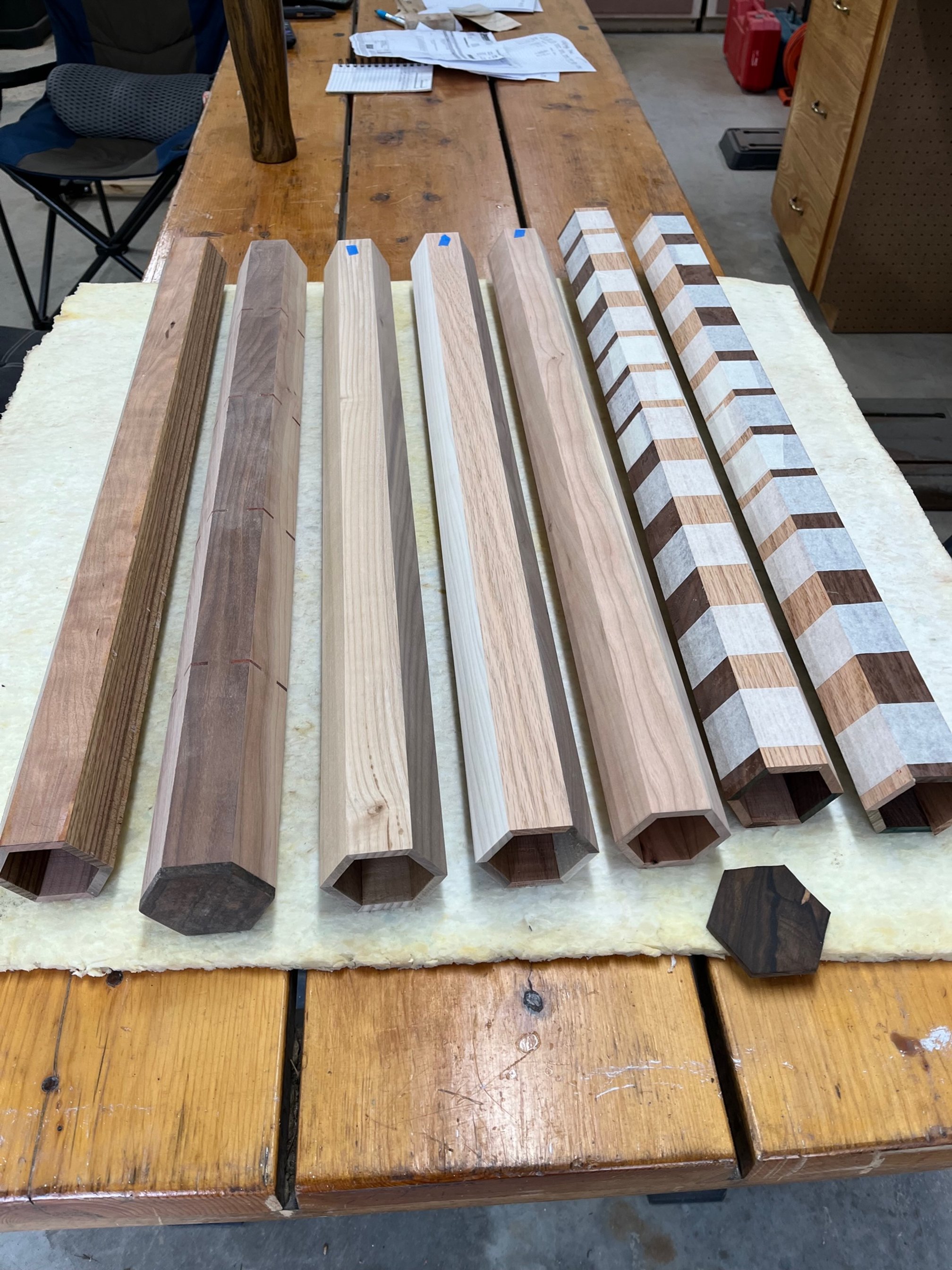

Cut to proper length and width, Ready to bevel, pick pieces, arrange grains, and glue up.

Glue curing under expensive clamps.

Moving right along. The cases are starting to talk to me by now.

Nice selection. Bottom end caps next.

Bottom end cap with foam to protect flyrod sections.

Truing stick making sure spline slots are cut exactly right.

All set to make slots for 12 splines of contrasting hardwood.

Here is what happens when you lose your focus. Very expensive firewood!!!

Cutting splines. Still have all my fingers.

Nice fit!

Trimming the splines then to sander to try for perfection.

Bottom section of rod case cap with channel for strap and top section ready to glue as one.

Glued top cap sections under pressure.

Setting the female section of the snap. Top of cap edges are rounded over and pad attached.

Two receiving parts of bronze rivets are secured with AC glue.

Finished cap of contrasting hardwoods and leather strap.

Sanded, final inspection, dusted, ready to apply finish.

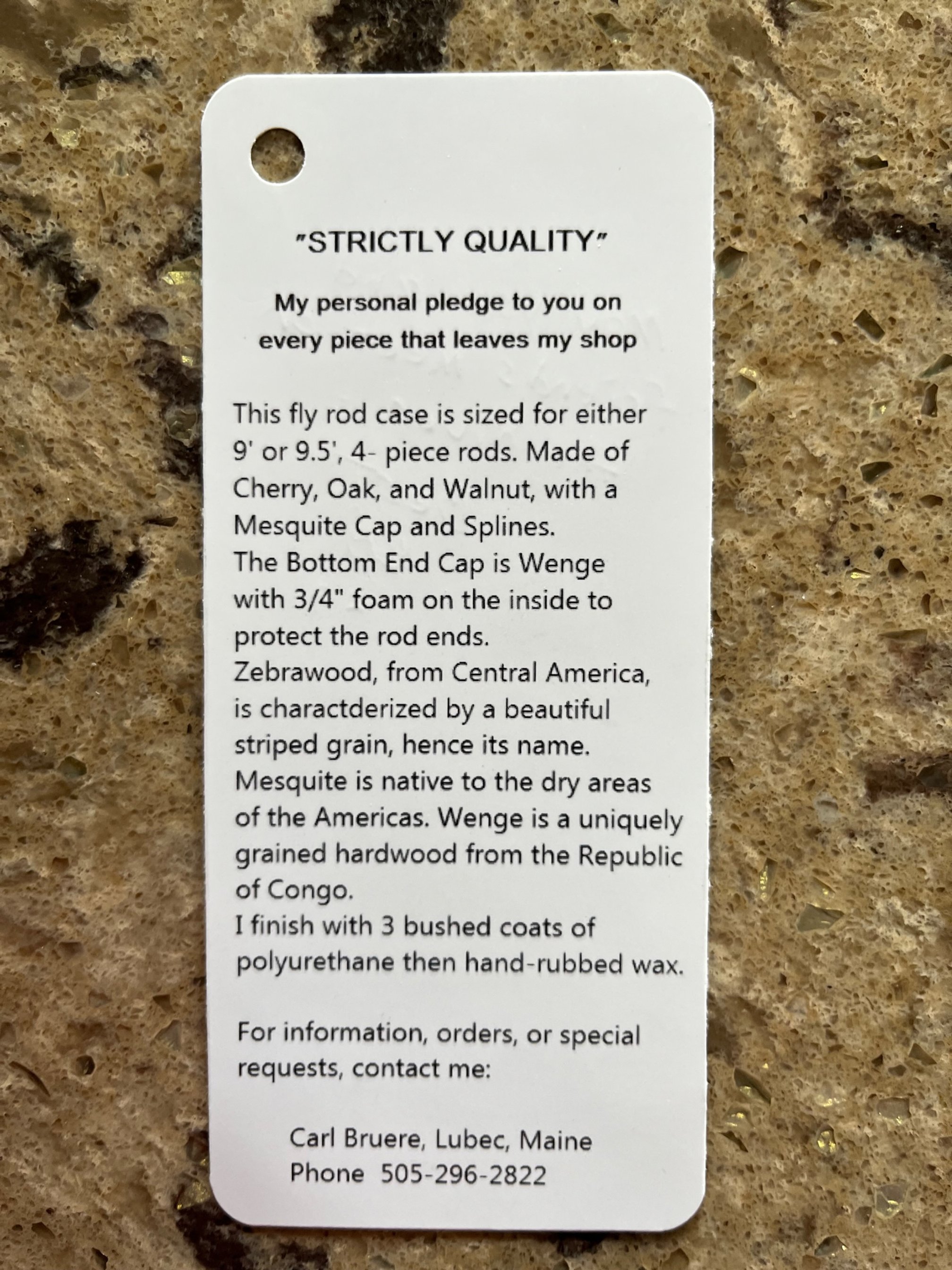

Cases get 3 brushed-on coats of varnish. Sanded to 220 grit between coats. A coat of wax completes the process.

Caps during finishing.

Finish coat of Howard’s Feed-N-Wax applied with 0000 steel wool. Love the feel. Enhances the beauty and depth of the wood grain.

Product card provides information for that specific fly rod case.

Shipping tubes at the ready.

Securely packaged.

Custom crafted.